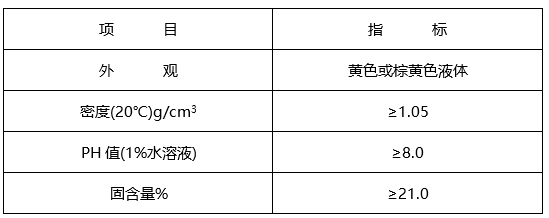

2. Physical and chemical indexes of ethylene glycol corrosion inhibitor:

3.ethylene glycol corrosion inhibitor performance characteristics:

(1) In the closed ethylene glycol aqueous solution system has excellent corrosion inhibition performance, and has good corrosion inhibition effect on carbon steel, stainless steel, copper and aluminum in the heat exchange equipment in the system.

(2) can effectively inhibit the acid migration of ethylene glycol solution, suitable for different concentrations of ethylene glycol solution concentration, can be randomly regulated according to the site water quality.

(3) The agent does not contain toxic and harmful components that can cause environmental pollution, and can be used with confidence, and there is no need to worry about environmental pollution that may be caused by sewage and the impact load on sewage treatment.

(4) Good dispersion performance, can effectively prevent the deposition of various dirt, so that the system can operate economically even in the case of dirt deposition, and the effect is excellent.

(5) The product/price ratio is excellent, which can reduce the treatment cost for users to the maximum while ensuring the water treatment effect.

4.ethylene glycol corrosion inhibitor use:

As a special disperse corrosion inhibitor for ethylene glycol solution, it is widely used in chemical, metallurgical, electric power, petrochemical, air conditioning and other closed systems.

Five, ethylene glycol corrosion inhibitor use method:

The dosage varies according to the water quality index and parameters, and the dosage is calculated according to the amount of supplementary water (the first dosage is based on the amount of retained water), and the dosage concentration is controlled at about 1000-2000 mg/L. Suitable for PH 7.0-10.0.

Six, ethylene glycol corrosion inhibitor packaging storage:

Packed in 25kg plastic drum, store in a cool and dry place for 12 months, handle with care to prevent impact.